Reducing risks and increasing SCADA network reliability

In previous articles, we looked at different types of networks, security, redundancy, cable types and how to best leverage your network. In this article we continue to explore crucial aspects of SCADA networking, including environmental risks and their impact on reliability, as well as some different networking product options.

Reliability and environmental risks

Industrial and commercial Ethernet networks utilise the same LAN standard, however the environments they work in are very different, with the design and specification of network components more challenging in industrial applications.

In commercial applications, network cables are typically hidden within wall cavities, in trunking or ceilings, or under floors. Network switches and associated hardware are normally installed in humidity and temperature-controlled environments, typically away from sources of heat, corrosion, vibration, moisture and direct UV exposure.

On the other hand, in industrial applications many cables, switches and other network components are often subject to harsh and potentially hazardous environments. This means many commercial off-the-shelf (COTS) Ethernet hardware solutions are not suited for industrial applications or environments where the key requirements are durability, reliability and physical performance.

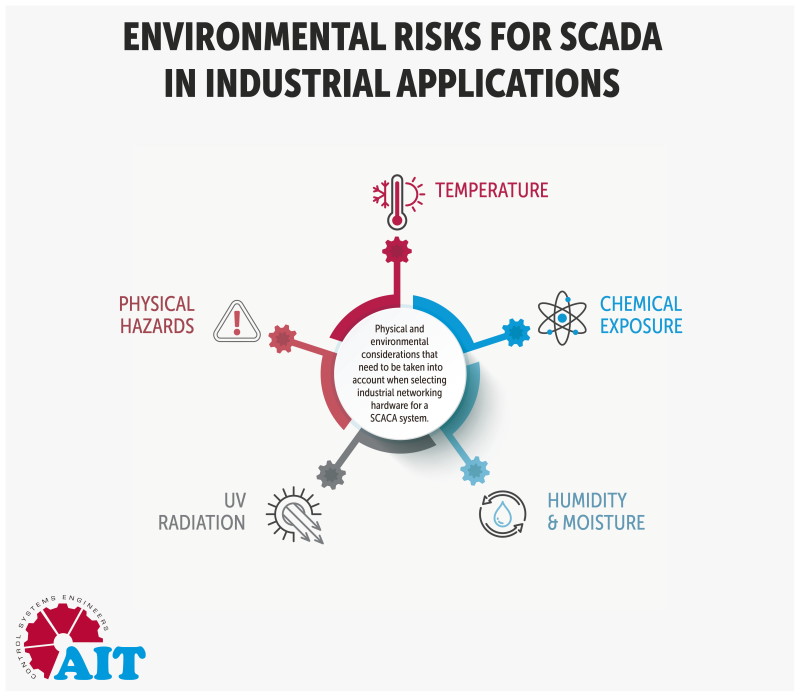

There are a number of physical and environmental considerations that need to be taken into account when selecting industrial networking hardware, including:

Temperature: Commercial products are generally designed to operate in a temperature range of 0oC to +40oC, making them unsuitable for more extreme heat and cold. Extreme high temperatures (>60º) typically cause the sheath and insulation material to degrade, which can increase attenuation and cause partial or total failure of the cable. Extreme cold can cause cables to become stiff and brittle, opening them up to cracking and allowing moisture to penetrate. Industrial-grade networking cables are designed to operate in a wider temperature range and can typically withstand temperatures of -40oC to +80oC, in specialist applications the temperature range is even wider such as -70º to +150ºC.

Chemical exposure: Commercial products are typically not suitable for applications where oils, fuels, solvents, cleaning solutions or corrosive gas environments are present, these gases or chemicals can cause a breakdown of the material with many side-affects including melting, swelling or a loss of mechanical strength. Corrosive chemicals (either liquid or airborne) are usually incompatible with commercial hardware and can easily damage electronic components, PCB’s, connectors, plastic housings etc. Industrial products are designed for a long life in harsh environments, some even have the option of conformal coating to minimise the damage to the electronic components caused by airborne corrosive chemicals, salt spray etc.

Humidity & Moisture: Commercial products are not generally suitable for exposure to moisture or excess humidity, they are typically designed for indoor use in a humidity-controlled environment. Industrial-grade products are designed to withstand much higher humidity levels and exposure to a wider range of temperatures, which can be conducive to the production of condensation. Industrial-grade products also offer various levels of ingress protection (IP) as outlined by international standards, up to and including IPX8.

UV Radiation: Many commercial products do not have the same level of UV protection and degrade very quickly if not installed within their design limits. Materials that are not UV resistant end up promptly fading, cracking, losing mechanical strength and pose potential safety risks where electrical wiring is involved, due to the rapid breakdown of conductor insulation. Industrial products are designed to be installed in many different areas of a particular installation, including outdoors, so are able to withstand various levels of ultra-violet (UV) radiation without degradation for extended periods of time, typically years.

Physical hazards: Commercial products are not typically designed for continuous movement or installation where vibration is a factor, any strain upon the product can lead to distortion or failure. Many industrial processes contain physical hazards including elevated levels of movement, vibration, strain, pressure or heat, sometimes all at once. Industrial-grade components are ruggedly built and hardened to withstand such environments, measures to improve reliability and integrity of the products include vibration dampers, armoured sheaths and covers, insulated metal connectors and strain relief mechanisms.

Vendor options

There are numerous vendors that supply industrial networking products including switches, terminals, cabling (copper and fibre optic), connectors and associated interfaces. Industrial switches and associated plug-in modules are designed with long life spans and a suite of network and security configuration tools, the main vendor products utilised in automation and control systems include:

- Cisco

- ConneXium by Schneider Electric

- Hirschmann

- Moxa

- Scalance by Siemens

- Stratix by Allen Bradley

The brand and type of switch, cabling, connectors and associated interfaces is dependent on many things, including the size of the network, the network architecture, managed or unmanaged switches, the layer level, rack or rail mount, the clients site specific requirements, environmental considerations, the bandwidth requirements including what traffic is anticipated, protocol requirements and any specific standards that must be adhered to (DNP3, IEC61850 etc.), further information on the technical aspects can be found in the following links:

Networks and Switches: Making the most out of your SCADA

Automation IT works closely with authorised Australian distribution channels for all brands and can provide full support for our clients if there are any manufacturing issues with the products within the specified warranty periods. Many of the vendors can also offer the option of extended warranties of up to seven (7) years, this shows the confidence they have in their products.

Making networking less complex

Installing a SCADA network is complex, with numerous considerations to take into account and decisions to make, for critical applications it is imperative to get it right the first time. It’s important to select an experienced electrical and control systems engineering company such as Automation IT to ensure the networking hardware, software and other components are correctly chosen to ensure any security, environmental and safety risks are minimised and the system remains reliable and secure in the long term.

Automation IT is able to design, configure, implement and commission high quality, end-to-end networking solutions for a wide range of industries and clients. Automation IT are vendor neutral, so is able to offer solutions that are tailored to best meet the requirements of the project and ensure the end client gets the most out of their network and assets.

With qualified engineers on staff, Automation IT’s solutions comply with all laws, standards and warranties, giving clients peace of mind that their system will be designed and integrated correctly the first time.