Standardised control systems benefit water and wastewater facilities

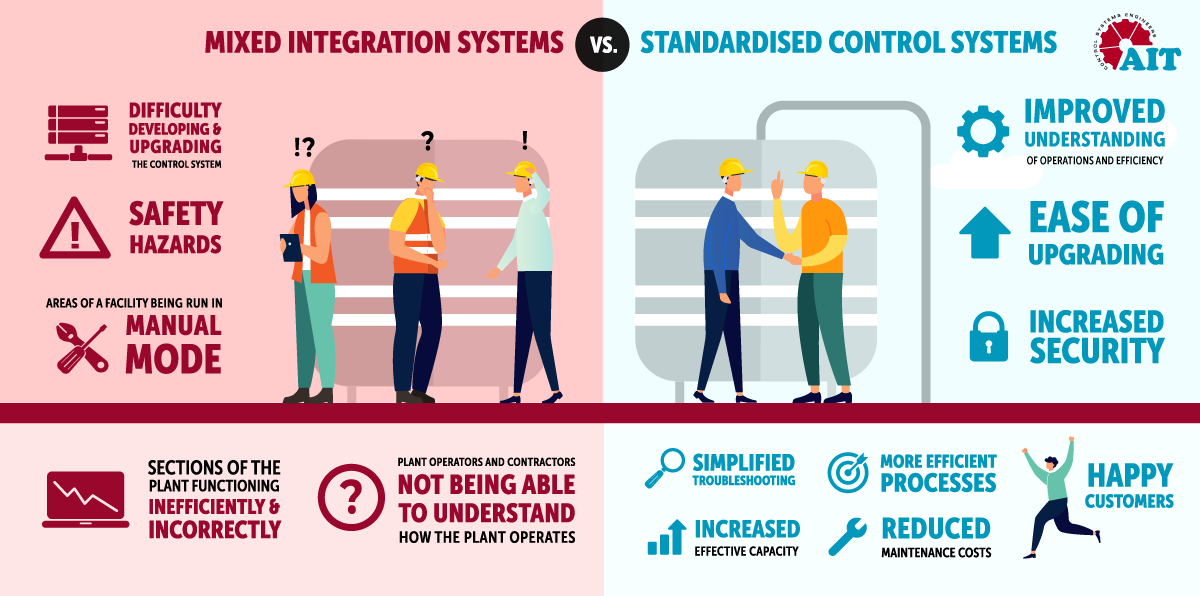

Control system integration improves efficiency and ensures consistent operations at water and wastewater facilities. It is important when implementing these systems that they are standardised across the application as a mixed system can become increasingly unstable, preventing the site from operating efficiently or safely.

A standardised system for water and wastewater facilities is important to ensure that community and businesses have access to adequate and high-quality water supply.

When implemented correctly, control systems can assist water and wastewater facilities by reducing energy costs, making processes more efficient, reducing maintenance costs, and increasing effective capacity.

But, these benefits can be compromised if the control system isn’t standardised.

A mixed integration system is often the result of different stages of augmentation where each section has been automated at different times and by different companies, leading to a lack of standardised programming, hardware and communications, and obsolete or missing plant equipment still existing in PLC logic and SCADA graphics.

This can result in:

- Plant operators and contractors not being able to understand how the plant operates

- Sections of the plant functioning inefficiently and incorrectly

- Difficulty developing and upgrading the control system

- Areas of a facility being run in manual mode

- Safety hazards

Therefore, there are a number of benefits to ensuring control systems are standardised across a site.

Ease of upgrading

According to Geoff Bladon, Business Development Director at Automation IT, one of the biggest challenges of a mixed control system is being able to upgrade it.

“In order to upgrade a system, a systems integration engineer needs to be able to read the code and make changes to ensure it is correct, up to date, and doing what it was intended to,” Mr Bladon said.

“This becomes increasingly difficult with mixed integration systems as there is a greater chance that bad coding practices have been used and that the correct documentation has not been provided for all areas. This includes drawings, software standards, and operation manuals, which inform the systems engineer what has been done in the past.

“Having the correct documentation enables the site to maintain plant design consistency in the future as system engineers can refer to this information, allowing for ease of upgrading and ensuring consistent coding can be maintained.”

Updated equipment

Control systems began gaining popularity from the 1960s with an increase in the need for monitoring and controlling equipment. Early systems were built with a generic ‘one shoe fits all’ approach to various markets.

But, as with all technology, control systems have also become more advanced and are now tailored to different industries and needs.

“Water and wastewater facilities with mixed control systems may also be using outdated technology which might not be suited to the application it is being used in,” Mr Bladon said.

“This can cause problems as the system will not be providing the most benefit. Up-to-date systems will lead to greater efficiency and cost savings.”

Improved understanding of operations and efficiency

Having a standardised control system ensures that plant operators and contractors can fully understanding how the plant operates.

“Mixed control systems can lead to a plant having sections that function inefficiently and incorrectly, making it difficult to understand how the whole plant operates and to make informed decisions,” Mr Bladon said.

“Standardised systems provide plant operators and contractors with improved code and plant functionality, allowing for faster troubleshooting, and greater data access for both operator and management reporting. This, in turn, allows for more informed decision making, leading to reduced downtime and greater plant efficiency.”

Improved functionality

Mr Bladon said Automation IT have helped water and wastewater facilities improve efficiency and operations by upgrading and standardising their control systems.

“Our engineers are highly experienced in control systems for water and wastewater facilities and have worked with asset owners to standardise their facilities, which has improved facility efficiency, and saved money through improved operations and reduced maintenance,” Mr Bladon said.

“We are independent technical experts, and are not attached to any one brand, ensuring we are able to provide an end-to-end solution that is tailored to meet the requirements of our clients.

“We also create fully-documented code, and comply with all laws, standards and warranties, making the operation and future maintenance of equipment easier, and ensuring operations can remain standardised as the facility grows.”